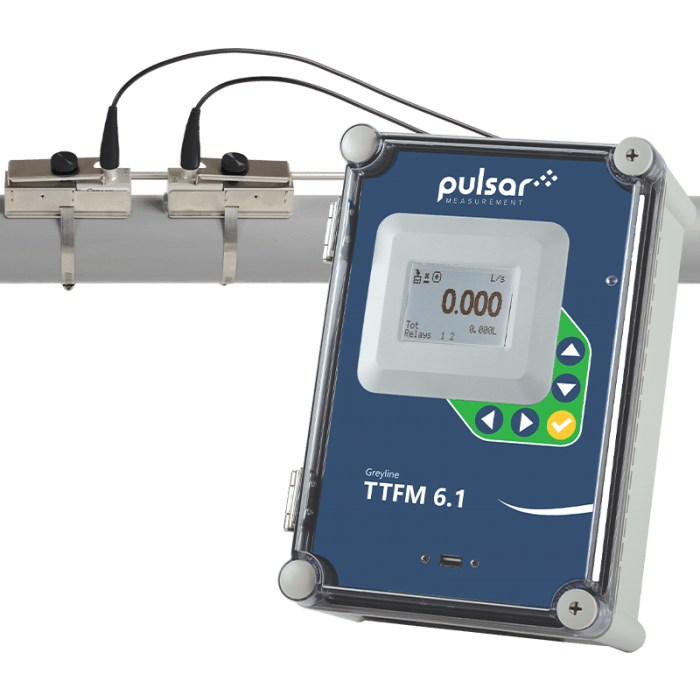

TTFM 6.1

- Easy Mounting, Single Head Sensor

12mm to 1200mm - Wide Flow Rate

Velocity: +/-0.02 - 12 m/s - PC Software

Built-in datalogger and retrieval software

Accurately measure the flow rate of clean, non-aerated liquids like water, chemicals, and oils in full pipes. Ultrasonic transducers mount on the outside of a pipe without shutting down flow. Flow rate is displayed on the large, backlit display along with totalizer and signal strength. Use the built-in control relays for flow alarms or flow proportionate pulse. Connect the isolated 4-20mA output to PLC's or controllers.

The TTFM 6.1 works on a wide range of pipe sizes and materials including carbon steel, stainless steel, ductile iron, cast iron, PVC, PVDF, fiberglass, copper, brass, aluminum and pipes with bonded liners including epoxy, rubber and Teflon.

The TTFM 6.1 Transit Time Flowmeter operates by measuring the “transit time” or “time of flight” for ultrasonic sound pulses transmitted from one transducer to another. Depending on the mounting configuration, the signal may cross the pipe once, twice or four times. To measure flow the transit time is compared between ultrasonic signals travelling upstream and downstream.

| General Specification | |

|---|---|

| Operating Parameters |

For clean liquids in full pipes with less than 2% solids or gas bubbles |

| Calibration | B and menu uilt-in 5-key calibrator with English, French Spanish language selection |

| Electronics Enclosure |

Watertight and dust tight NEMA4X (IP 66) polycarbonate with clear, shatterproof cover |

| Accuracy |

± 1% of reading from 1.5 to 40 ft/sec (0.03 m/sec), whichever is greater 1% Repeatability & Linearity: ±0.25% |

| Display | White, backlit matrix - displays ,14-digit totalizer, relay 5-digit flow rate with floating decimal status, operating mode and calibration menu |

| Power Input | 100-240VAC 50-60Hz (see Options), Watts maximum (with standard features) |

| Output | Isolated 4-20mA/0-5V, 1000 ohm load maximum, programmable offset |

| Control Relays | 2 programmable flow alarm and/or flow Relays, form 'C' dry contacts rated 5 amp SPDT; proportional pulse |

| Operating Temp. (electronics) | -5° to 140°F (-20° to 60°C) |

| Transducer Specification | |

|---|---|

| Pipe Diameter |

½ to 48” (12 mm to 1200mm ) |

| Pipe Materials | Any metal or plastic sonic conducting material including carbon steel, stainless steel, ductile iron, cast iron, , aluminum PVC, PVDF, fiberglass, copper, brass and pipes with bonded liners including epoxy, rubber and Teflon |

| Flow Velocity |

± 0.07 to 39 ft/sec ( 0.02 to 12 m/sec) typical |

| Operating Frequency |

1.28 MHz |

| Operating Temperature | -40° to 300°F (-40° to 150°C) |

| Transducer Mounting Kit | Includes set of stainless steel pipe clamps, and coupling compound |

| Transducer Cables | RG-58 coaxial, 25 ft (7.6 m) with BNC connectors and seal jackets |

| Certification | Non-incendive for Class I Division 2, Groups A,B,C,D hazardous locations |

Water networks

Ultra clean water

Chemicals & Acids

Hydraulic oils